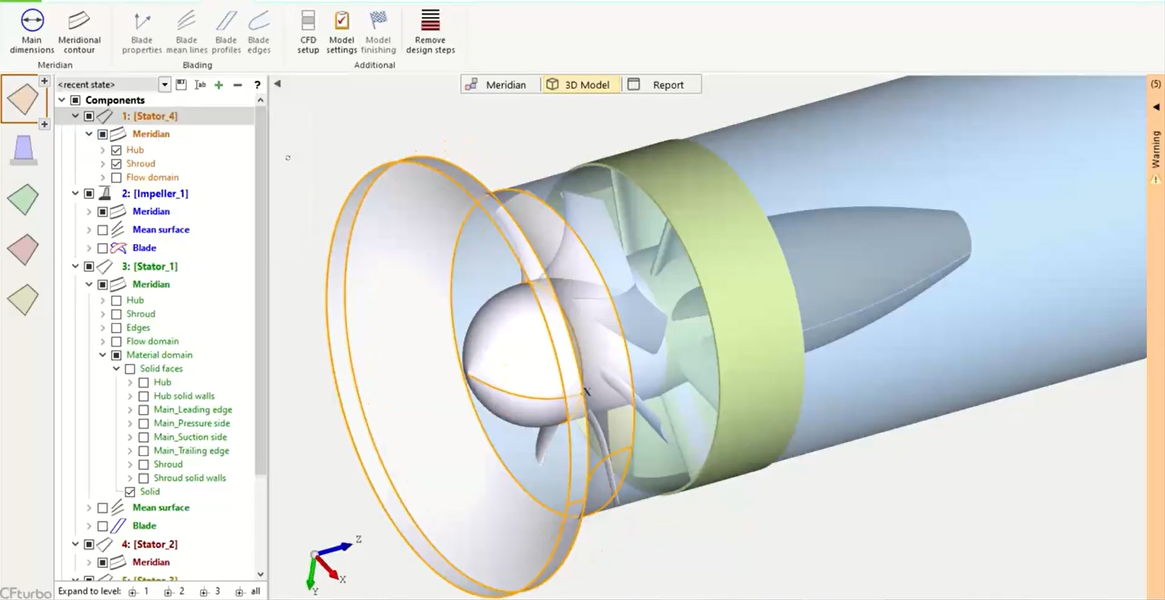

CFTURBO IN ANSYS WORKBENCH: A STREAMLINED WORKFLOW OF HYDRAULIC PUMP DESIGN, 3D-CFD-SIMULATION AND OPTIMIZATION FOR A CRYOGENIC ROCKET TURBOPUMP With its latest release CFturbo 2020.R1, a new, streamlined workflow for Turbomachinery design, meshing, simulation, design exploration, and optimization is available on the market. It is a fully bi-directional integration of CFturbo in ANSYS Workbench, which can be done manually-interactive, or automated. In this one-hour webinar hosted and produced by Empowering Pumps, subject matter experts from CFTurbo and ANSYS will show an initial hydraulic design of a cryogenic rocket turbopump – including an inducer, impeller, diffuser, and volute – as well as the workflow within ANSYS Workbench. In ANSYS, the experts will demonstrate model set-up, meshing, preparation of simulation, post-processing, and design exploration.

CFturbo软件是德国CFturbo GMBH公司开发的专业的叶轮机械设计软件。CFturbo软件结合了成熟的旋转机械理论与丰富的实践经验,基于理论方程与经验函数库,广泛应用于泵、风扇、鼓风机、压缩机、涡轮等的整机设计,包括转子、导叶、扩压器、蜗壳等部件。针对旋转机械的设计及优化改进,CFturbo功能完备且在细节上非常贴合设计人员的习惯,其主要特点有:

1、设计功能完备,覆盖全比转速范围,满足2D和3D造型设计,以及针对某些特定设计需求的能力,如复合叶片、污水泵、双蜗壳、二次回流通道设计、结构体加厚设计等。

2、具备大量源于工程积累的经验设计函数,且按照叶轮机械类型做了细分,例如前弯式离心风机和后弯式离心风机所采用经验函数不同,体现细节和专业性。

3、界面友好,易用性强,具备性能预估能力,提供多种真实物性模型。

4、接口丰富,软件开放,可与仿真优化软件无缝集成,快速实现设计-仿真-优化的一体化流程。

5、具备的参数化设计功能,不但支持用户进行初始参数化设计得到新的三维模型,同时支持导入已有模型实现逆向设计,为工程师提供了优化设计方向完备的CAD/CFD/CAE接口,在此基础上进行设计改进与性能优化。

添加客服微信,加入技术交流群。